I have wanted to put a door on my ultimaker for a while now, to help stabilize temperatures inside and keep prints from pulling off the build plate. I feel like it’ll also give the machine a bit more of a professional look which is always fun.

Continue reading “Ultimaker Door”Lessons from making 5 side lit signs

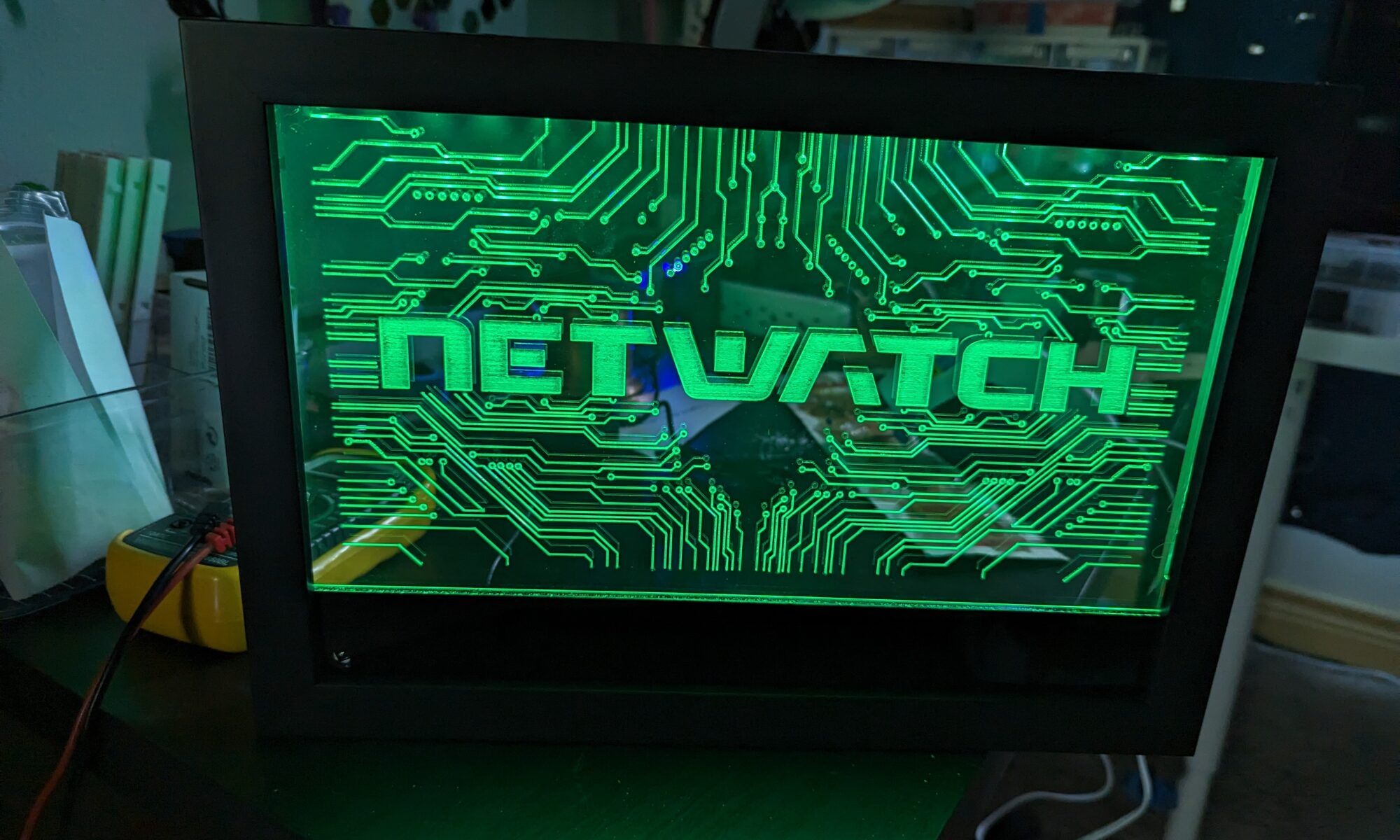

I made a single acrylic sign for myself and as a test piece before I started making 5 of them for Christmas presents. Now that I’ve finished those 5, I have a few lessons that I learned along the way that my original sign didn’t shake out of my design and method.

Continue reading “Lessons from making 5 side lit signs”Making LED Acrylic Signs

Now that I have a CO2 laser available, it opens up some new things that I can do, like cutting and engraving clear acrylic. Adding some side lighting to that and we can make a pretty sweet sign. I also plan on making a few more of these for gifts, so this first one is my experiment piece to try out all the techniques needed.

Continue reading “Making LED Acrylic Signs”Wood Working on the Gweike Cloud

Wood cutting and engraving is great on the Gweike cloud. As one expects from a CO2 laser, its much faster than the ortur I was using before and I had to play quite a bit to find some good settings for the new laser to optimize the performance.

Continue reading “Wood Working on the Gweike Cloud”Getting Started on the Gweike Cloud Pro

After having used a diode laser for a while, it had proven itself as a useful tool for my workshop. So what’s the next step to go from there, obviously a CO2 laser with more power and speed than the diode laser. I wanted a desktop model in the 50w+ range and found it in the Gweike cloud pro laser cutter. It has a similar feature set to other desktop models and supports LightBurn and local control (a major boon over the likes of GlowForge and despite the “cloud” part of the Gweike Cloud name).

Continue reading “Getting Started on the Gweike Cloud Pro”InkScape and LightBurn

Unable to Perform Path Operations

If you can’t do boolean operations in InkScape, you may have to un-group the paths. It can’t do path operations on groups, and sometimes InkScape will put a single object into a group. You can combine paths and do boolean operations on them that way, but that is using the path combine tool, you just cannot use the grouping feature.

LightBurn Limitations

You can’t use object operations on it for LightBurn to understand it. No use of object clip or mask should be used when creating files for use in LightBurn. You can make use of path difference or intersection to make changes to similar effect when avoiding the object tools.

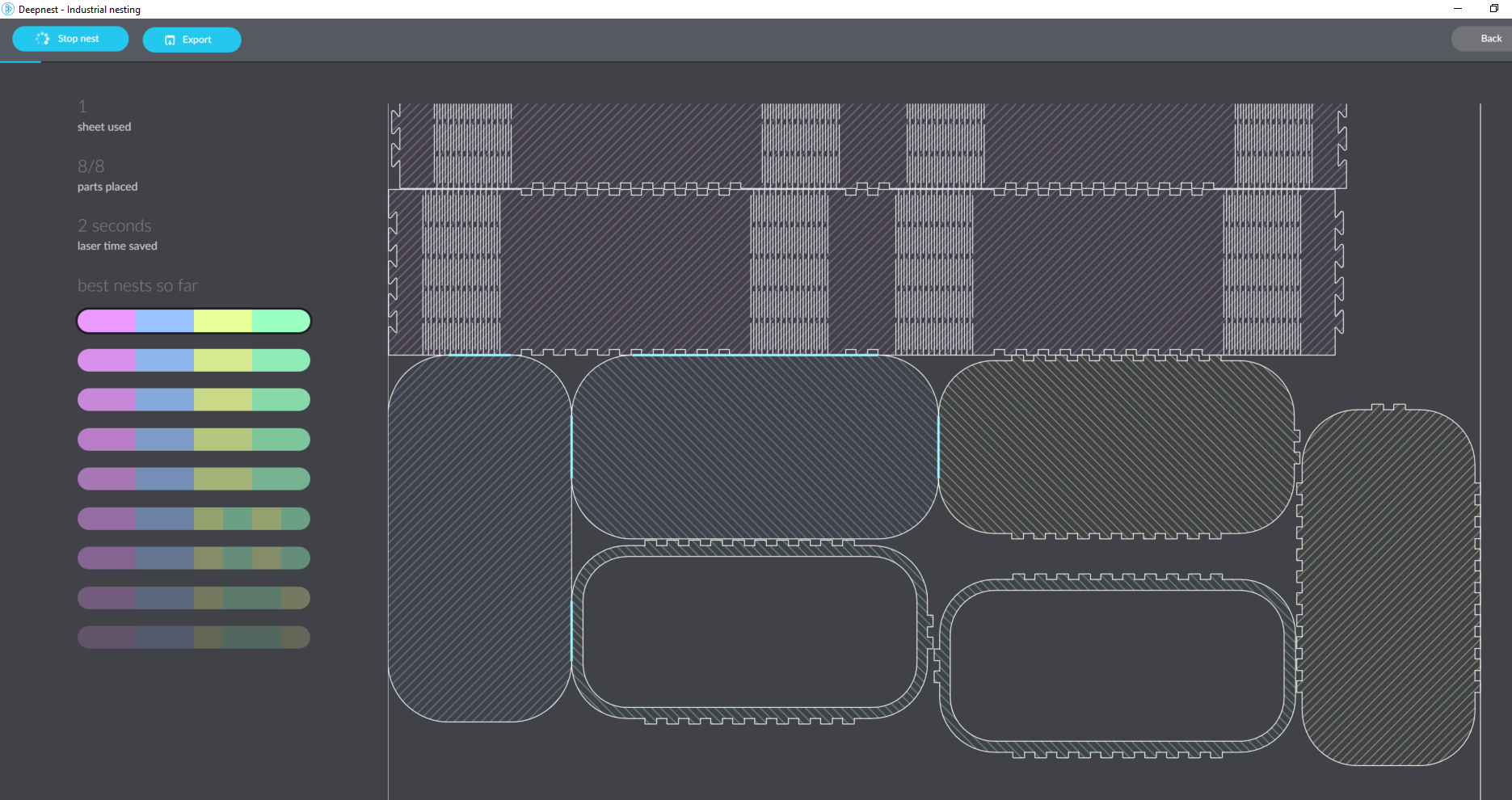

Using DeepNest and LightBurn to Optimize Laser Cutting

DeepNest is a software package to optimize part placement in laser cutting designs. It works out very well for maximizing your usage of material and avoiding unnecessary waste. I’ve started using it combined with Boxes.py in order to part out wooden boxes and position them onto sheets to try and maximize the number of boxes fitting.

Continue reading “Using DeepNest and LightBurn to Optimize Laser Cutting”Cutting Fabric with the Ortur Laser Master 2 & SVG Types

While trying to cut some fabric with the Ortur Laser Master 2, we ran into a strange curiosity in light burn. We found that different SVG types generated different GCode for the same shape. After this we managed to put together a table of cutting settings for various fabric colors.

Continue reading “Cutting Fabric with the Ortur Laser Master 2 & SVG Types”New LightBurn Features (aka I probably didn’t read the release notes months ago)

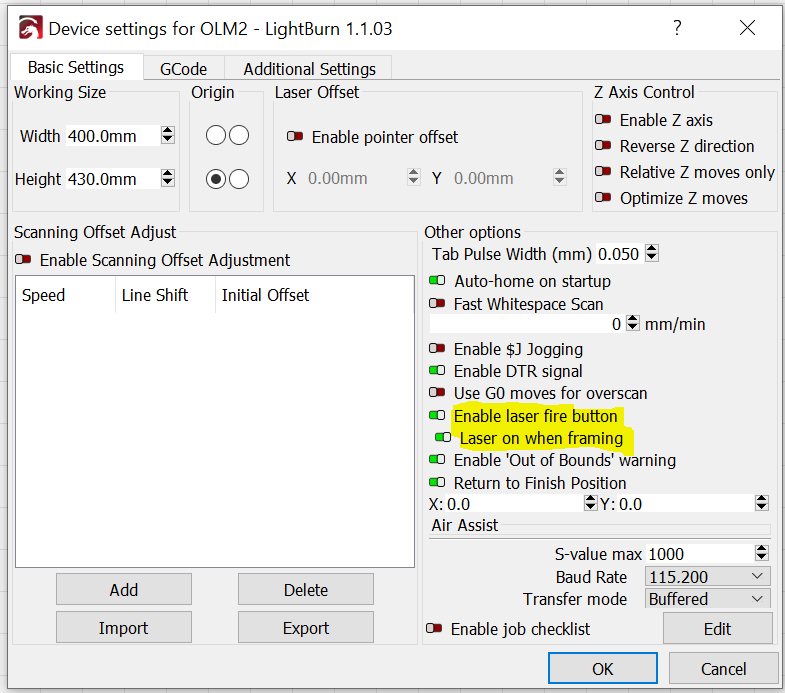

I can’t believe I missed this option being added to LightBurn. In the device settings, there is now an option to enable is the laser on when framing option. This turns on the laser with a low power setting when running the frame to make it obvious where you will be cutting/engraving. This replaces holding shift when hitting the frame button from older releases. This small quality of life improvement is much appreciated here.

WLED Notice of Laser Cutter Use

I have a laser cutter in my office that I use from time to time. I close the door when its running because you need safety glasses on while its running, but since I use my office for other things, the door closed doesn’t necessarily mean safety glasses are needed. To make this simpler, I decided to try and make some automations to notify when the laser is running. I want to use a WLED strip around the door and light it different colors based on laser operating status (and other statuses in the future).

Goals

- Set the WLED strip to red when the laser starts cutting

- Set the WLED strip to the previous settings (or turn it off) when the laser stops cutting