DeepNest is a software package to optimize part placement in laser cutting designs. It works out very well for maximizing your usage of material and avoiding unnecessary waste. I’ve started using it combined with Boxes.py in order to part out wooden boxes and position them onto sheets to try and maximize the number of boxes fitting.

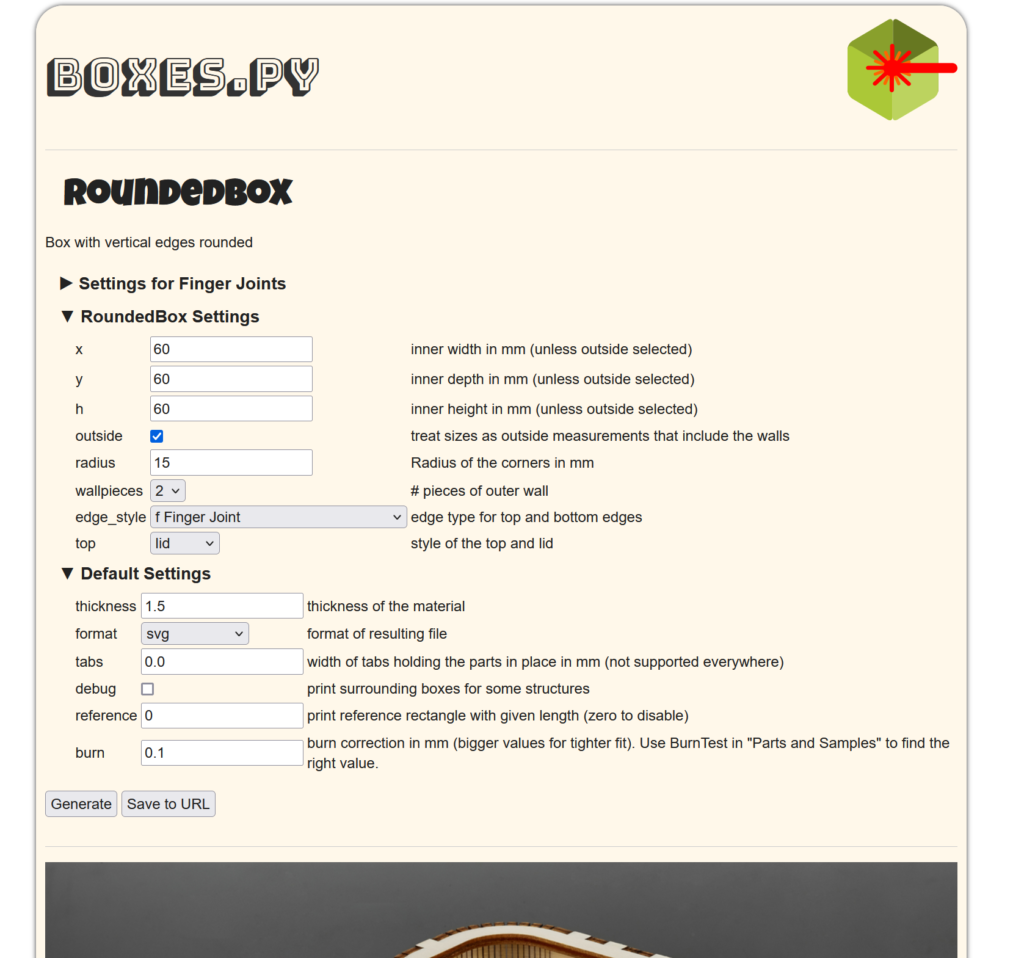

Let’s start in boxes.py to get something worth nesting in DeepNest.

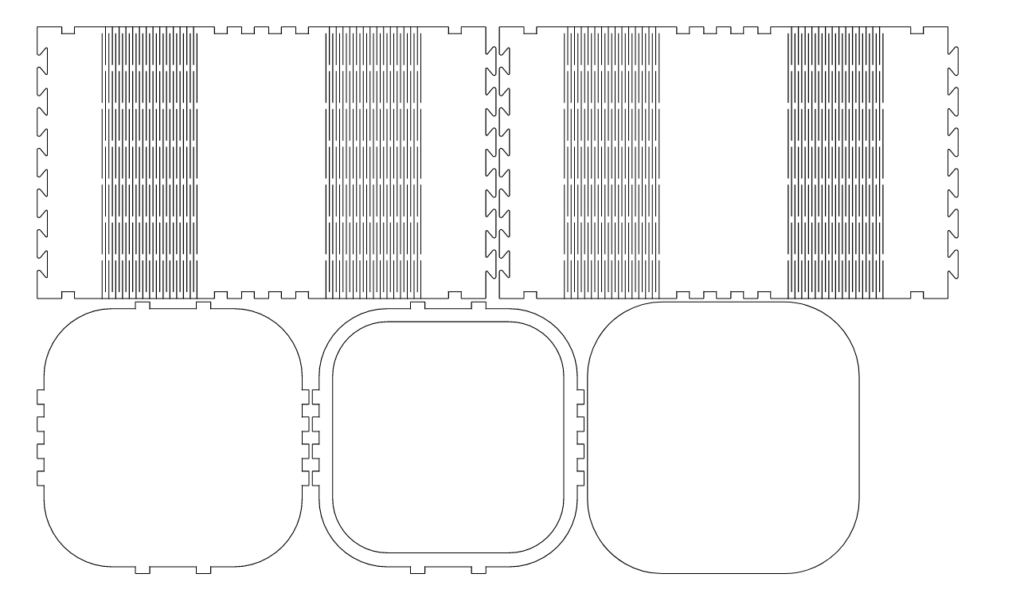

We’ll generate the SVG and save it out into a file. The parts can all be in one file, or multiple files holding all the parts you want to nest.

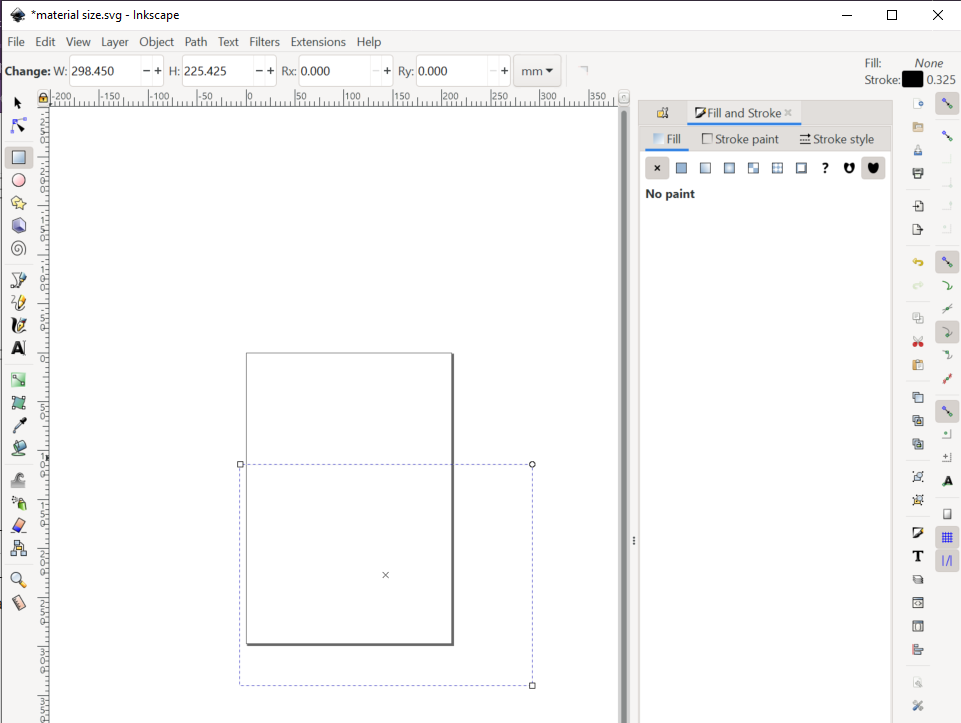

Next up, a rectangle the size of the material we have available needs to be created in InkScape.

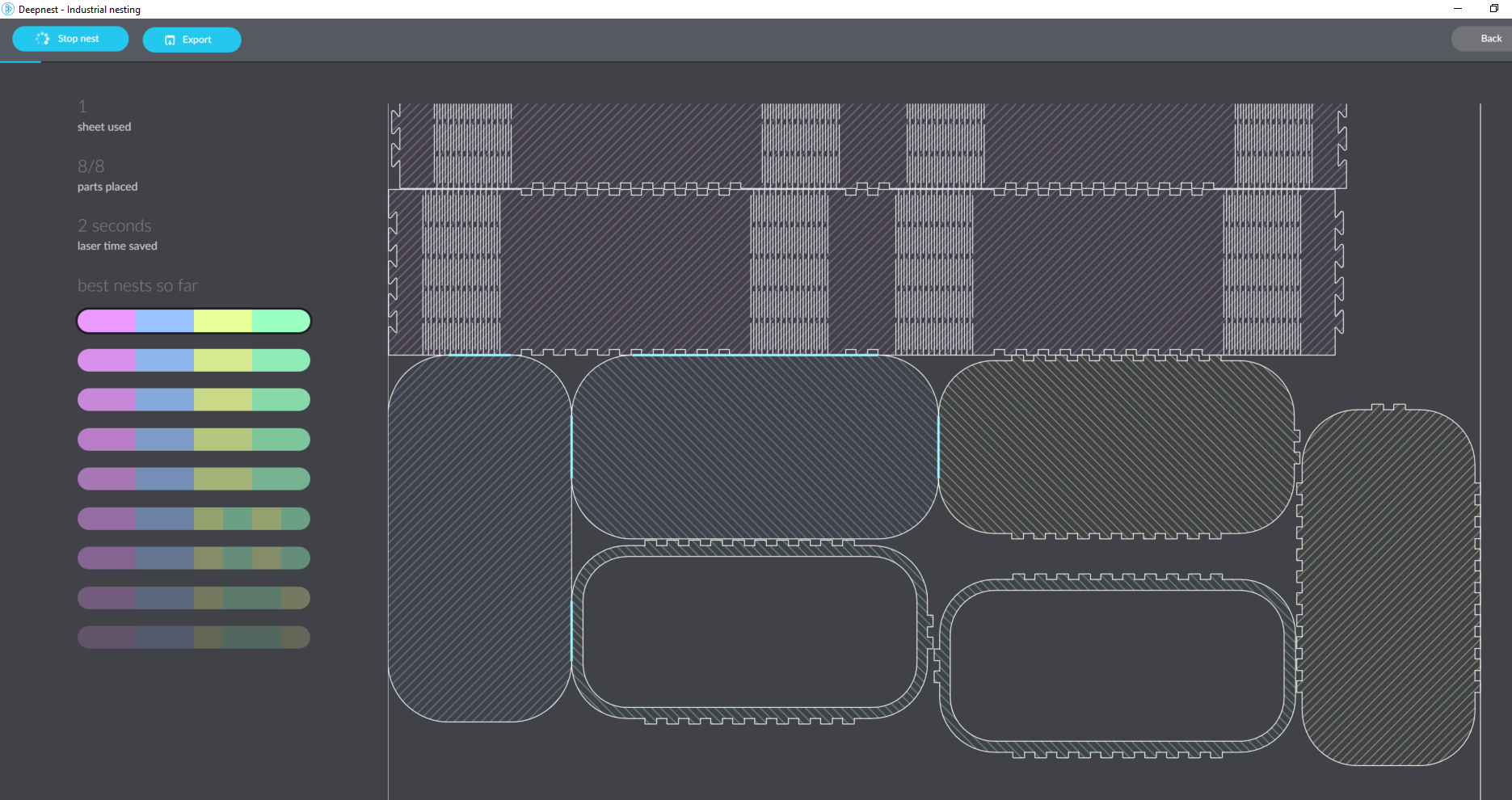

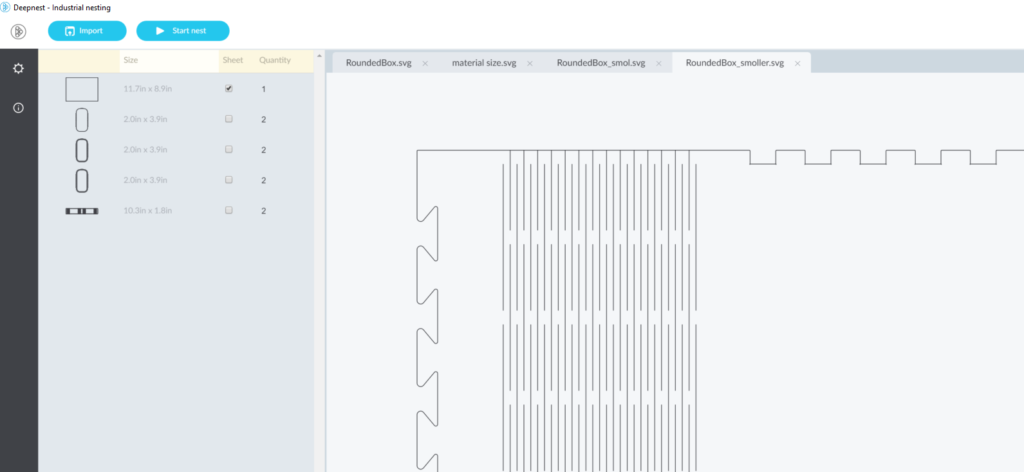

Import the file from boxes.py into DeepNest, it’ll split everything up by part. We’ll also need to import the inkscape box for the material size.

We’ll want to select our InkScape material size box as the sheet in deepnest so it knows to fit the parts into it’s boundary. Next we start nesting in DeepNest.

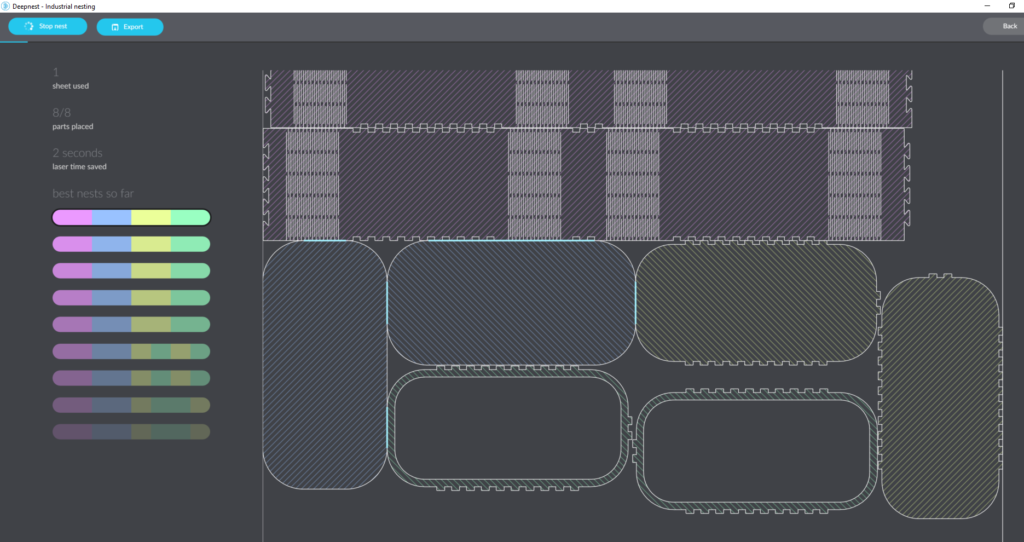

DeepNest well keep running as long as you let it. I’ll let it run until I know that either the parts won’t fit on my sheet, or until they’re all placed on the sheet. Export from DeepNest to svg, add it to Lightburn and go.

Conclusion

Even if you don’t need the nest optimization of DeepNest, it’s still exceedingly useful for ensuring you can fit the parts on the wood sheets you have available. The software is exceptionally easy to use and a good tool for any laser cutting tool box.