After having used a diode laser for a while, it had proven itself as a useful tool for my workshop. So what’s the next step to go from there, obviously a CO2 laser with more power and speed than the diode laser. I wanted a desktop model in the 50w+ range and found it in the Gweike cloud pro laser cutter. It has a similar feature set to other desktop models and supports LightBurn and local control (a major boon over the likes of GlowForge and despite the “cloud” part of the Gweike Cloud name).

Continue reading “Getting Started on the Gweike Cloud Pro”Building a Word Clock

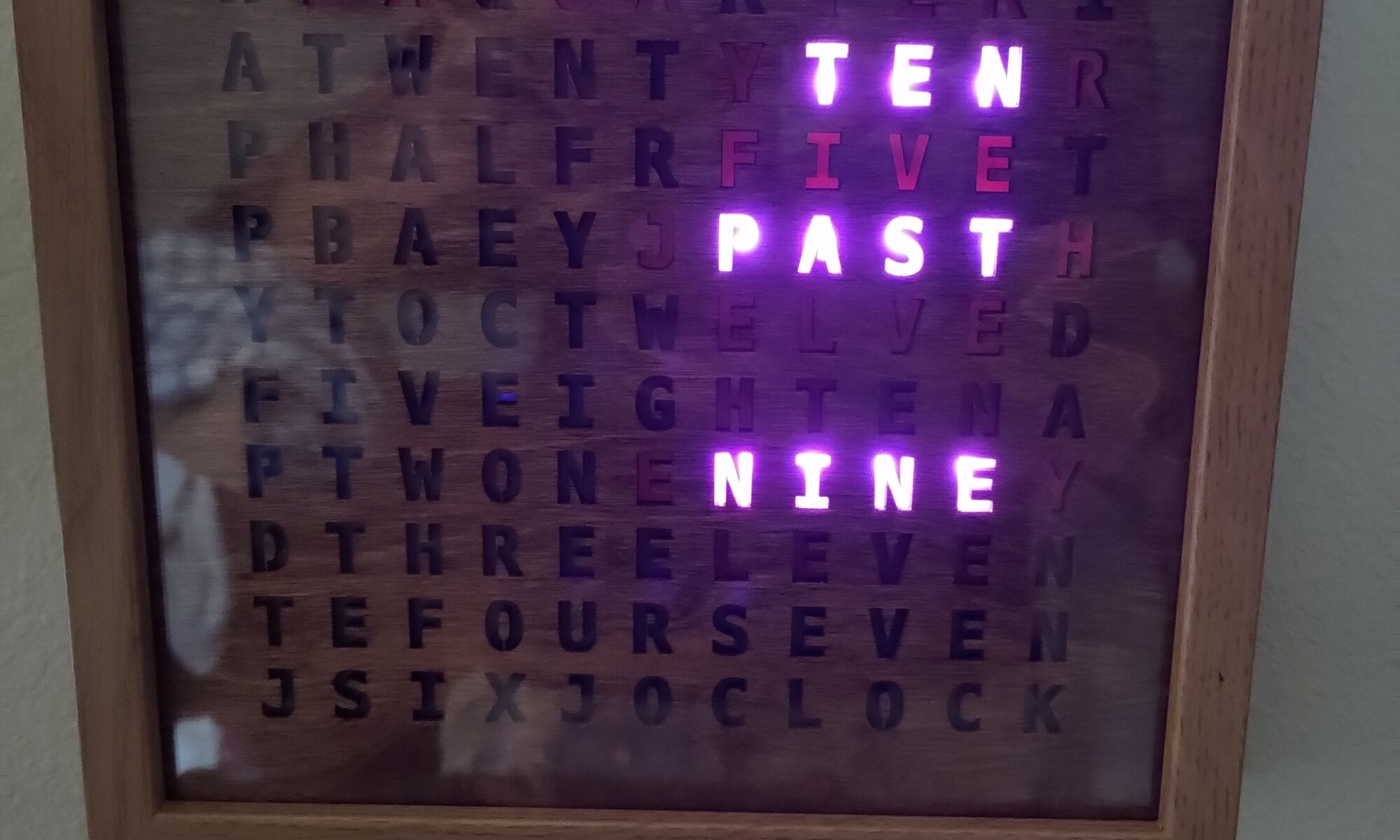

Way back around 2013, something started getting popular on Instructables, word clocks. They gave the time as a sentence instead of a usual number like most common clocks. I thought these were cool and wanted to build one, I even picked up parts, but never got around to building it.

Continue reading “Building a Word Clock”InkScape and LightBurn

Unable to Perform Path Operations

If you can’t do boolean operations in InkScape, you may have to un-group the paths. It can’t do path operations on groups, and sometimes InkScape will put a single object into a group. You can combine paths and do boolean operations on them that way, but that is using the path combine tool, you just cannot use the grouping feature.

LightBurn Limitations

You can’t use object operations on it for LightBurn to understand it. No use of object clip or mask should be used when creating files for use in LightBurn. You can make use of path difference or intersection to make changes to similar effect when avoiding the object tools.

Adding an LPS22 to AirGradient and Building a Custom Sensor in EspHome

I picked up some extra sensors for my AirGradient DIY kits and didn’t realize at the time that they’re not officially supported in EspHome. So with that I went on the journey of adding my own custom sensor code to EspHome to run them.

Continue reading “Adding an LPS22 to AirGradient and Building a Custom Sensor in EspHome”Using DeepNest and LightBurn to Optimize Laser Cutting

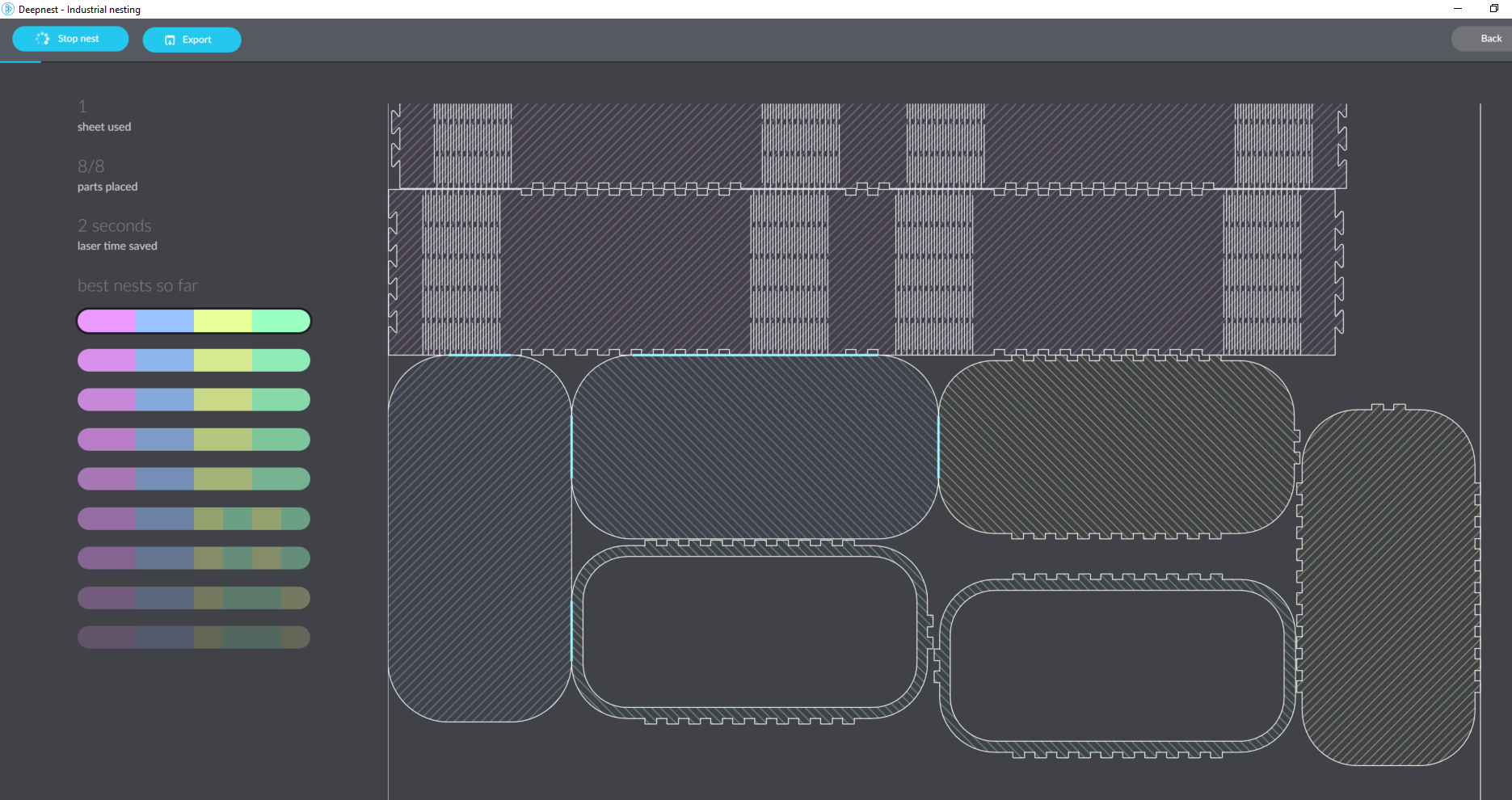

DeepNest is a software package to optimize part placement in laser cutting designs. It works out very well for maximizing your usage of material and avoiding unnecessary waste. I’ve started using it combined with Boxes.py in order to part out wooden boxes and position them onto sheets to try and maximize the number of boxes fitting.

Continue reading “Using DeepNest and LightBurn to Optimize Laser Cutting”Catia V5 Shortcut Keys

I’ve had an 8 key macro pad on my desk for a while now and haven’t been making very good use of it. Since I’ve been doing a bit more CAD work, why not setup some macros for CATIA.

Continue reading “Catia V5 Shortcut Keys”Various CAD Designs

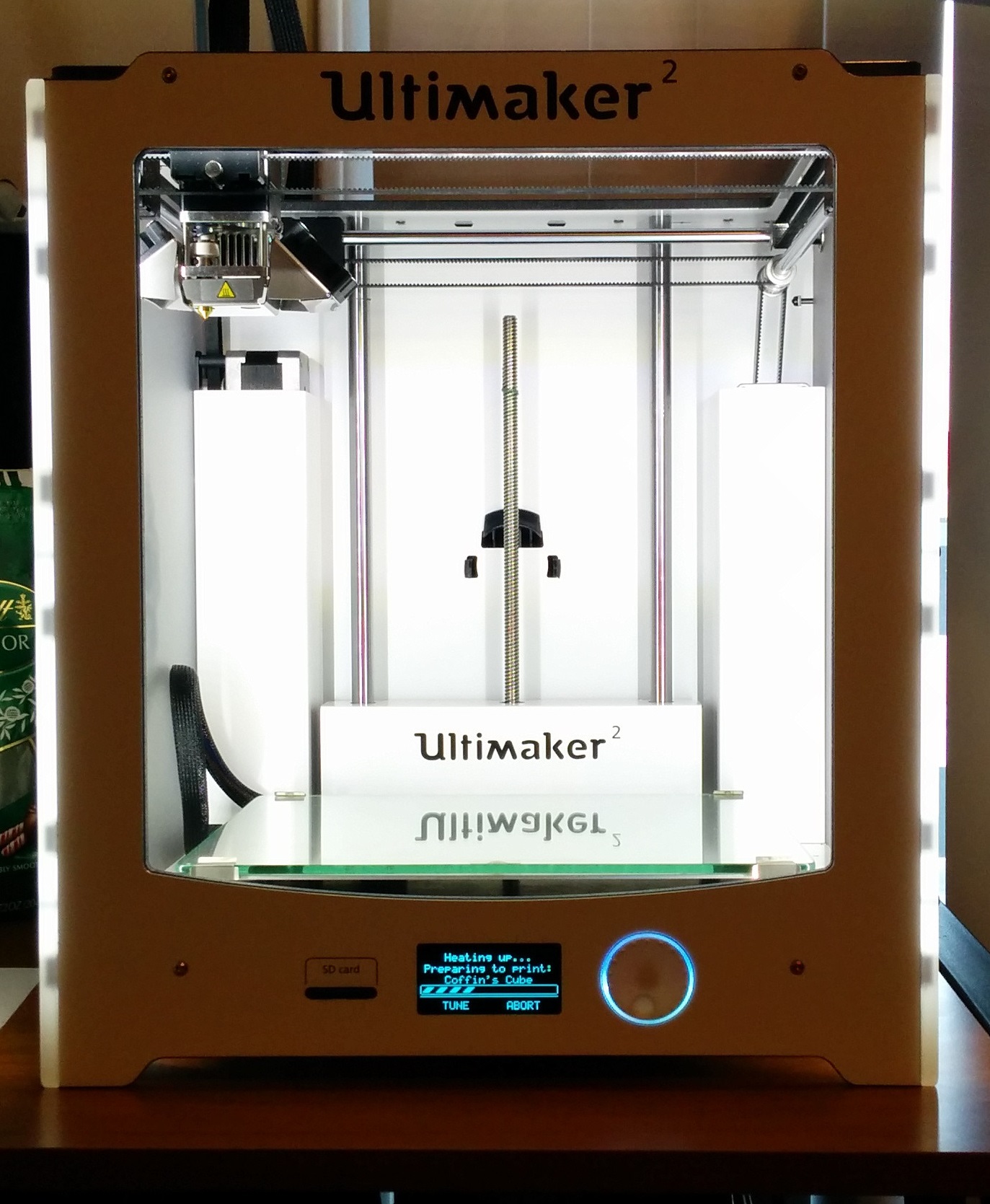

This is just a showcase of some of the CAD designs I’ve made for various projects. I’ve made some functional enclosures as well as some pieces to hold art. Most of these are 100% designed by me, but the EspDeck case I used a few designs from Thingiverse as sources, and merged them together in a way that best suited my end goal.

Continue reading “Various CAD Designs”Cutting Fabric with the Ortur Laser Master 2 & SVG Types

While trying to cut some fabric with the Ortur Laser Master 2, we ran into a strange curiosity in light burn. We found that different SVG types generated different GCode for the same shape. After this we managed to put together a table of cutting settings for various fabric colors.

Continue reading “Cutting Fabric with the Ortur Laser Master 2 & SVG Types”Improve CATIA STL Output Accuracy

CATIA is pretty good at times at hiding options, so here we’ll find out how to increase the export accuracy of STL files from CATIA. The defaults used give some pretty rough models especially around curves, so we’ll be increasing the accuracy to get smoother models to use on our 3d printer.

Continue reading “Improve CATIA STL Output Accuracy”New LightBurn Features (aka I probably didn’t read the release notes months ago)

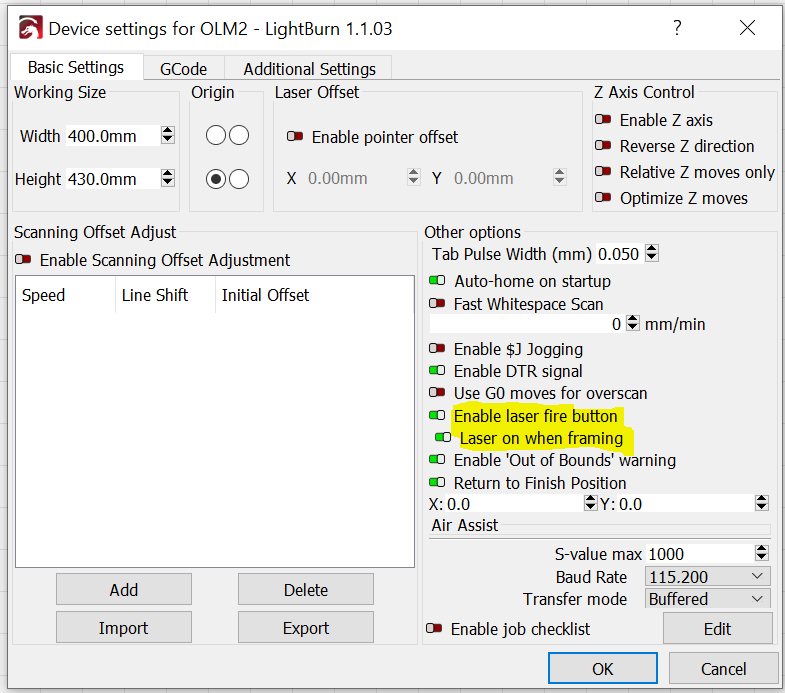

I can’t believe I missed this option being added to LightBurn. In the device settings, there is now an option to enable is the laser on when framing option. This turns on the laser with a low power setting when running the frame to make it obvious where you will be cutting/engraving. This replaces holding shift when hitting the frame button from older releases. This small quality of life improvement is much appreciated here.