We have one material for my 3D printer that is very temperamental on the build plate. Printing using it and a clean build plate will lead to the print not sticking midway through and failing, while printing on glue stick or tape leads to it sticking so well it takes 30 minutes with a razor blade to remove it. Anything that seems to help it stick, helps it stick a bit too much, and my build plate is glass, so i can’t flex it to pop the print off. In comes the dumb idea, why not use a sticky note underneath the tape. This will let us flex the print just enough to break the seal with the build plate. It worked. So here’s how to do it.

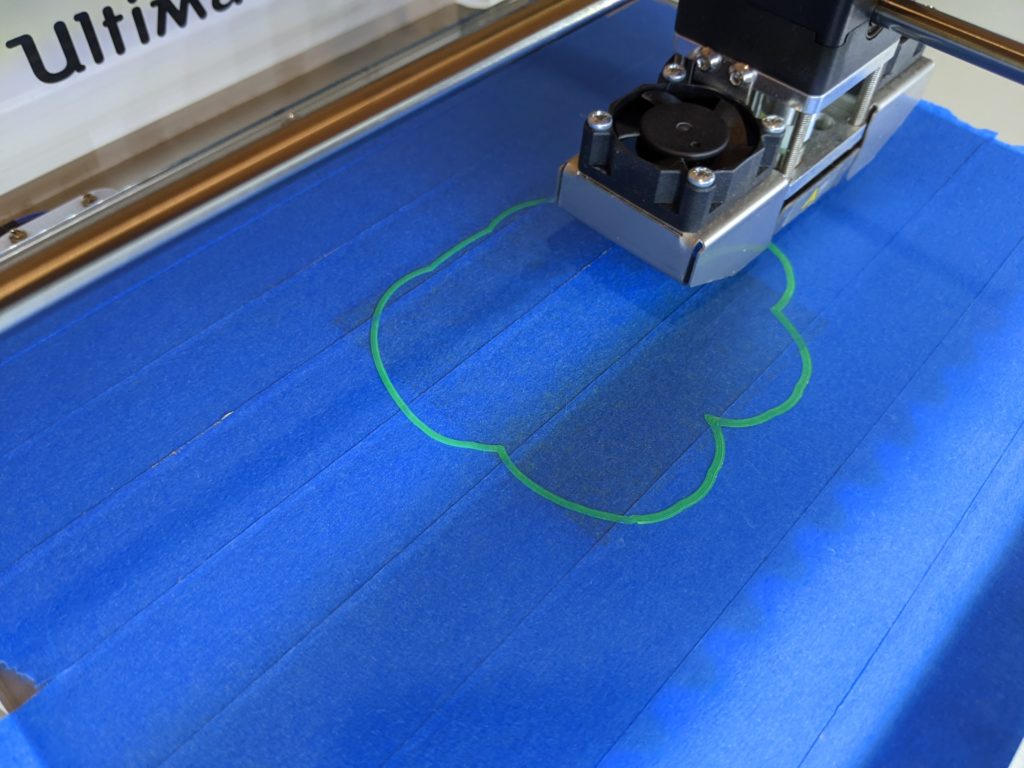

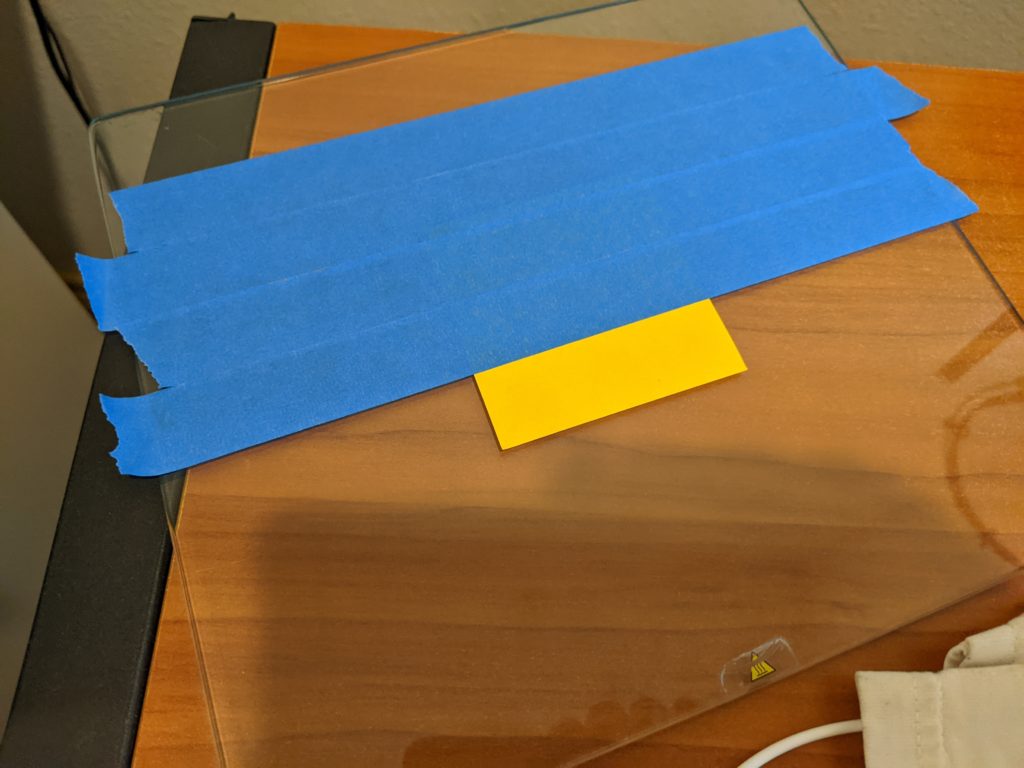

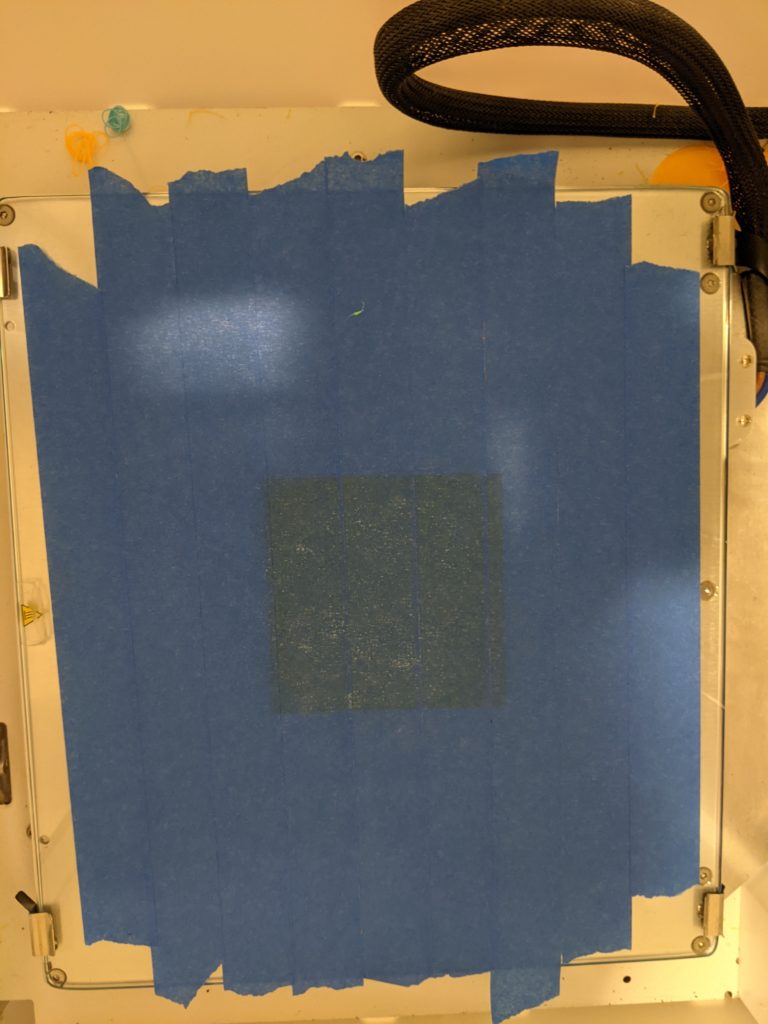

Start with a sticky note on the build plate where the object is going to be printed. In this case, the print is dead center and not much larger than the sticky note. Once the sticky note is in place, tape the build plate as usual with blue tape.

That’s it, just run the print. Once the print is done and the build plate cool, there should be enough flex available to break the bond with the build plate and not break the tape/sticky note. I only ran two prints through on this setup, so i don’t know how long it’ll last, but it does work.